However, navigating the cost of sticker printing can often feel like a complex puzzle, with prices varying widely based on a multitude of factors. Understanding these elements is key to securing the best value for your sticker needs in the Philippine market.

The most significant factors influencing sticker printing prices in the Philippines can be broken down into five core areas:

1. Material and Finish: The foundation of your sticker's price lies in its material. Paper stickers are generally the most economical choice, suitable for indoor use where durability isn't a primary concern (e.g., temporary labels, planner stickers). Vinyl stickers, on the other hand, offer superior durability, water resistance, and UV protection, making them ideal for outdoor applications, product labels, and long-lasting promotions. They command a higher price point.

Beyond the material, the finish also plays a significant role. Glossy finishes provide a vibrant, reflective look, while matte finishes offer a sophisticated, non-glare appearance. These standard finishes usually have minimal price differences. However, opting for specialized finishes like clear vinyl, holographic, metallic (chrome/gold), or a laminate layer (for added protection) will increase the cost. Laminates, while adding to the expense, significantly extend the life and resilience of your stickers, especially for high-touch items or outdoor exposure.

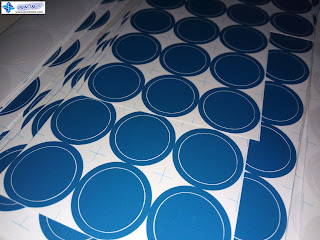

2. Size and Shape: Unsurprisingly, the physical dimensions of your sticker directly influence its cost. Larger stickers consume more material and ink, leading to higher prices. Small, standard-sized stickers (e.g., 1x1 inch to 3x3 inches) are typically the most budget-friendly.

Equally important is the shape. Standard shapes like circles, squares, and rectangles are usually more economical to produce because they require less complex cutting. Custom die-cut stickers, which are cut precisely to the outline of your design, incur additional costs. This is due to the need for specialized cutting equipment and the extra setup time involved in creating a unique cutting path. Kiss-cut stickers (where only the sticker itself is cut, leaving the backing intact for easy peeling), while often less expensive than full die-cuts, still add to the complexity compared to simple shapes.

3. Quantity: Perhaps the most significant determinant of the per-piece cost is the quantity you order. Sticker printing operates on economies of scale. The initial setup costs (design proofing, machine calibration, material loading) are relatively fixed, regardless of whether you print 50 or 5,000 stickers. Therefore, the more stickers you print in a single batch, the lower the cost per sticker will be. Most printers will have a Minimum Order Quantity (MOQ), below which individual stickers become prohibitively expensive. Ordering in bulk almost always results in substantial savings.

4. Printing Method: The technology used to bring your design to life also impacts the price.

Digital Printing: Ideal for smaller batches, quick turnaround times, and designs with many colors or gradients. It offers flexibility and is generally more cost-effective for low-to-medium quantities.

Offset Printing: For massive print runs, offset printing typically offers the lowest per-unit cost and superior color accuracy. However, it involves higher setup costs, making it less suitable for small orders.

Silkscreen Printing: Often chosen for its vibrant, opaque colors and durability, especially for outdoor applications or specific material types. It's usually more cost-effective for designs with fewer colors and larger quantities.

The most significant factors influencing sticker printing prices in the Philippines can be broken down into five core areas:

1. Material and Finish: The foundation of your sticker's price lies in its material. Paper stickers are generally the most economical choice, suitable for indoor use where durability isn't a primary concern (e.g., temporary labels, planner stickers). Vinyl stickers, on the other hand, offer superior durability, water resistance, and UV protection, making them ideal for outdoor applications, product labels, and long-lasting promotions. They command a higher price point.

Beyond the material, the finish also plays a significant role. Glossy finishes provide a vibrant, reflective look, while matte finishes offer a sophisticated, non-glare appearance. These standard finishes usually have minimal price differences. However, opting for specialized finishes like clear vinyl, holographic, metallic (chrome/gold), or a laminate layer (for added protection) will increase the cost. Laminates, while adding to the expense, significantly extend the life and resilience of your stickers, especially for high-touch items or outdoor exposure.

2. Size and Shape: Unsurprisingly, the physical dimensions of your sticker directly influence its cost. Larger stickers consume more material and ink, leading to higher prices. Small, standard-sized stickers (e.g., 1x1 inch to 3x3 inches) are typically the most budget-friendly.

Equally important is the shape. Standard shapes like circles, squares, and rectangles are usually more economical to produce because they require less complex cutting. Custom die-cut stickers, which are cut precisely to the outline of your design, incur additional costs. This is due to the need for specialized cutting equipment and the extra setup time involved in creating a unique cutting path. Kiss-cut stickers (where only the sticker itself is cut, leaving the backing intact for easy peeling), while often less expensive than full die-cuts, still add to the complexity compared to simple shapes.

3. Quantity: Perhaps the most significant determinant of the per-piece cost is the quantity you order. Sticker printing operates on economies of scale. The initial setup costs (design proofing, machine calibration, material loading) are relatively fixed, regardless of whether you print 50 or 5,000 stickers. Therefore, the more stickers you print in a single batch, the lower the cost per sticker will be. Most printers will have a Minimum Order Quantity (MOQ), below which individual stickers become prohibitively expensive. Ordering in bulk almost always results in substantial savings.

4. Printing Method: The technology used to bring your design to life also impacts the price.

Digital Printing: Ideal for smaller batches, quick turnaround times, and designs with many colors or gradients. It offers flexibility and is generally more cost-effective for low-to-medium quantities.

Offset Printing: For massive print runs, offset printing typically offers the lowest per-unit cost and superior color accuracy. However, it involves higher setup costs, making it less suitable for small orders.

Silkscreen Printing: Often chosen for its vibrant, opaque colors and durability, especially for outdoor applications or specific material types. It's usually more cost-effective for designs with fewer colors and larger quantities.

5. Additional Services: Beyond the tangible aspects of the sticker itself, additional services can contribute to the final price. If you don't have a print-ready design file, many printers offer design services, which will add to your overall expense. Similarly, rush orders, while convenient, almost always incur an additional fee because they require prioritizing your job over others. Finally, factor in the printer's location and delivery costs if you're not able to pick up your order directly.

Typical Price Ranges (Estimates in PHP - Philippine Pesos):

Given these myriad factors, providing exact price ranges is challenging, as the market is highly competitive and dynamic. However, to give you a rough idea for common requests (assuming good quantity, e.g., 100-500 pieces):

Small (1x1 to 2x2 inches) Standard Shape:

Paper: PHP 1 - 5 per piece

Vinyl (gloss/matte): PHP 5 - 20 per piece

Medium (3x3 to 4x4 inches) Standard Shape:

Paper: PHP 5 - 15 per piece

Vinyl (gloss/matte): PHP 15 - 40 per piece

Custom Die-cut: Expect a 20-50% increase over standard shapes of similar size and material, depending on complexity. Specialty materials (holographic, clear, metallic) will increase prices further.

These are general estimates, and prices can fluctuate based on the specific printer, current material costs, and order volume.

Tips for Getting the Best Value:

Know Your Requirements: Be clear about the material, size, shape, quantity, and intended use of your stickers before requesting a quote.

Get Multiple Quotes: Don't settle for the first offer. Contact several reputable local and online printers in the Philippines to compare prices and lead times.

Provide Print-Ready Files: If you have a high-resolution, vector-based design file (AI, EPS, PDF), you'll save on design costs.

Order in Bulk: If you anticipate needing more stickers in the future, ordering a larger quantity upfront will almost always be more cost-effective per piece.

Consider Standard Options: If budget is a major concern, opt for standard sizes, shapes, and materials before exploring custom or specialty options.

In conclusion, sticker printing prices in the Philippines are not static, but rather a reflection of material choices, design complexity, quantity, and printer capabilities. By understanding the variables at play and communicating clearly with your chosen printer, you can make an informed decision that balances quality and cost, ensuring your stickers make the desired impact without breaking the bank.

0 Comments:

Post a Comment